Modern 3D technologies are widely used in the automotive industry. 3D scanners are used not only in car design but also in the implementation of repairs and car tuning. The new technology has become a real breakthrough before the design of cars was carried out only by hand. However, even minor inaccuracies in the calculations seriously spoiled the vehicle’s appearance and worsened its aerodynamics.

It is possible to avoid design errors only if accurate calculations are made. The 3D scanner allows you to carry out this important work in automatic mode. 3D scanning has become an indispensable tool for professionals in the automotive industry, as it allows you to achieve maximum accuracy in the design of parts and solve complex problems in the shortest possible time.

NRing specialists involved in the repair, maintenance, and preparation of cars for the requirements of any Russian racing series needed help in obtaining the high-precision geometry of the KIA RIO front suspension. The most effective solution to this problem is using 3D scanning technology.

Running gear scanning was entrusted to RangeVision specialists since it is a manufacturer of 3D scanners and a software developer, its specialists know everything about the nuances of 3D scanning.

3D scanning with RangeVision equipment opens up a wide range of opportunities for professionals, allowing them to:

- speed up the process of manufacturing, repairing, or tuning a car;

- achieve a high level of accuracy;

- improve work efficiency;

- reduce the cost of the service;

- visualize the project.

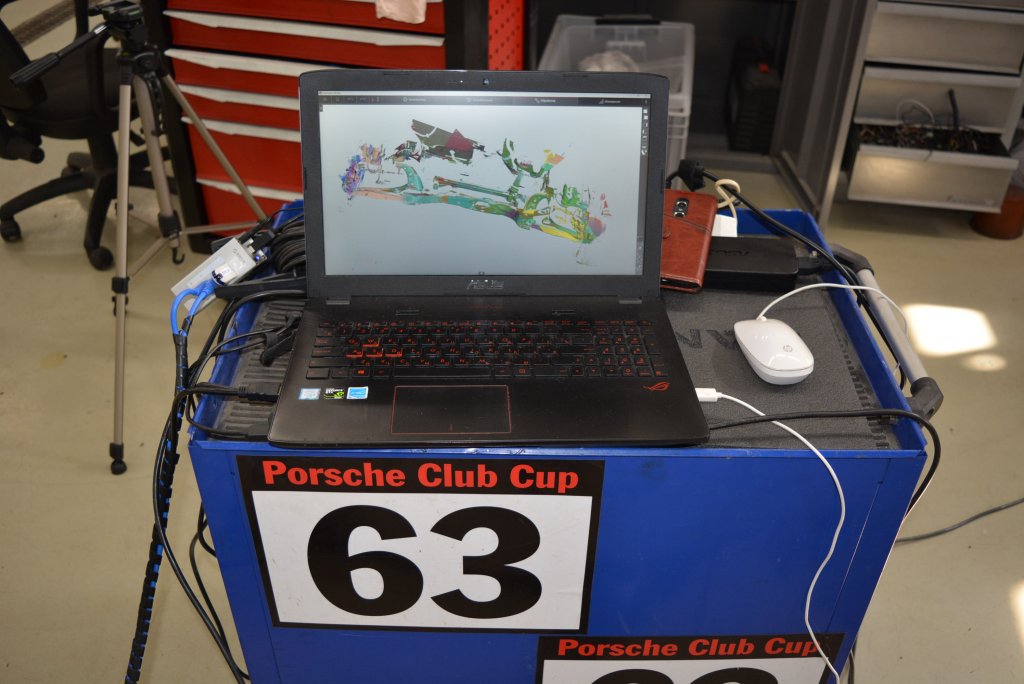

The customer needed to obtain the original surface of the chassis and engine mounting points for measuring and designing mounting brackets for a modified gearbox. After agreeing on the terms and scope of work, a RangeVision specialist with the equipment necessary went to the NRing service.

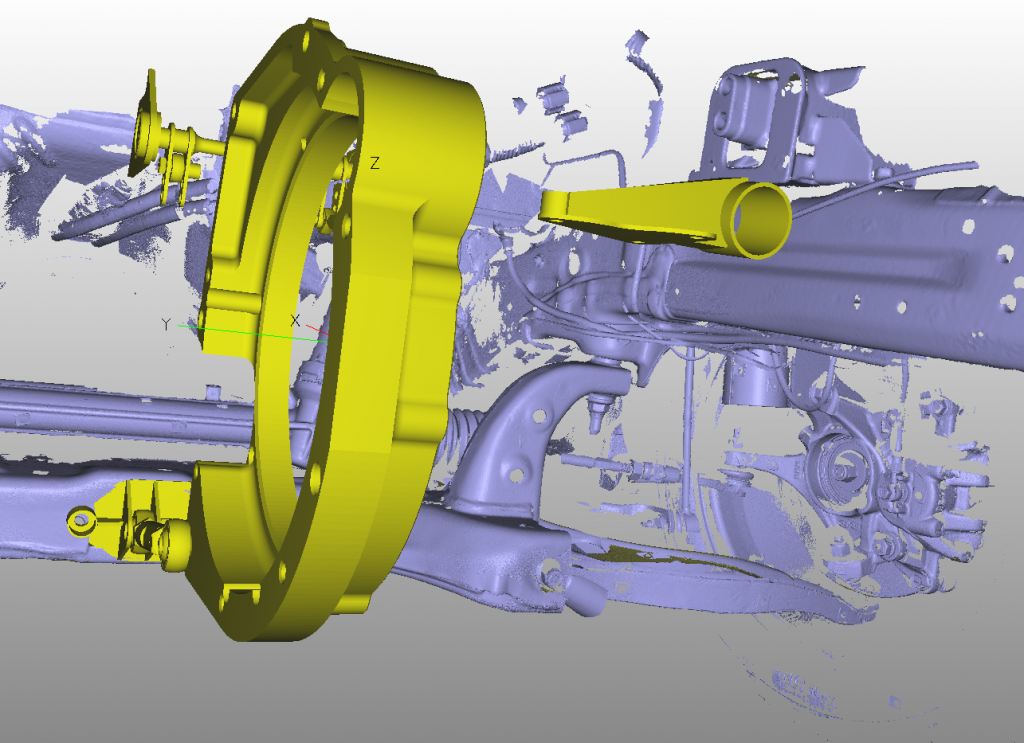

Digitization of the vehicle geometry was carried out with an industrial 3D scanner RangeVision PRO. The scan result with a high volumetric accuracy of less than 0.2 mm was prepared in STL format and sent to the customer within one day.

To optimize the design of the brackets fastening of the upgraded gearbox, the captured suspension geometry was set in the coordinate system of the 3D model provided by the customer.

Thus, 3D scanning has become part of great and laborious work to modernize and prepare the car for racing competitions.

Using a professional 3D scanner RangeVision PRO allows you to perform the high-precision design of car parts. The 3D scanner allows you to get a digital version in STL format with high resolution, including the small elements. The computer model of parts and its visual presentation allow you to visualize the result in detail and, if necessary, increase additional measurements, virtual tests, and design calculations without additional financial and time costs. Thanks to the results achieved in the process, the highest quality parts have been obtained, which fully met the requirements in the repair and adjustment of equipment specialists.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.