From energy research to metalworking: Everywhere, the laser offers opportunities to do more for a sustainable future. Today, lasers are already being used to weld battery cells for electromobility particularly efficiently. The laser can be used to measure pollutants in the atmosphere, and it is being used to build the quantum internet. The Fraunhofer Institute for Laser Technology ILT presented these and other innovations at this year’s LASER World of PHOTONICS and World of QUANTUM in Munich.

The LASER trade show in Munich celebrated its 50th birthday this year. With over 40,000 visitors, it was a good 30 percent above the pre-pandemic level, a clear sign of the economic relevance of laser technology. In addition, the trade fairs Automatica and World of QUANTUM were held at the same venue. On the one hand, this shows how strongly laser technology and mechanical engineering are networked today; on the other, new topics such as quantum technologies are accelerating the pace of innovation.

How closely laser technology is linked to basic research was demonstrated at the World of Photonics Congress. Dr. Tammy Ma from the National Ignition Facility at Lawrence Livermore National Laboratory and Prof. Constantin Häfner, the director of Fraunhofer ILT, spoke there in the Plenary Talk about the potential of laser-driven inertial fusion. The topic has raised great expectations as a future energy source – but it will also boost laser technology development.

Laser welding for extreme conditions

A snowmobile is definitely one of the most unusual exhibits at a laser fair. This year, however, Fraunhofer ILT displayed an electric snowmobile from the Finnish vehicle manufacturer Aurora Powertrains at its booth. The company uses cold-resistant batteries with extremely high energy density developed for Arctic temperatures. The joining technology for the IP67-rated batteries was customized in Aachen.

Aurora uses lithium-ion NMC pouch cells with 0.2 mm thin copper and aluminum electrical contacts. The cells are welded with a 1 kW single-mode fiber laser whose control electronics locally modulate the power. “We evaluated the idea, manufactured the first samples, and supported the Finnish startup in its further development,” explains Dr. Alexander Olowinsky, head of the Joining and Cutting department at Fraunhofer ILT. “Now we are supporting them in implementing it for large-scale production.”

Robust lasers for pollutant measurements from space

Experts at the Fraunhofer ILT have already been using lasers for climate research for several years. LIDAR (Light Detection and Ranging) systems, a form of three-dimensional laser scanning similar to radar, make an important contribution. There are earth-based, helicopter-based, or satellite-based systems. LASER World of PHOTONICS, Fraunhofer ILT presented exhibits on these three different variants. One of them is the satellite-based LIDAR system of the Franco-German climate mission MERLIN (Methane Remote Sensing LIDAR-Mission).

Methane is one of the most dangerous greenhouse gases. It is much more harmful to the environment than CO2. A precise study of where exactly it is emitted and where it disappears is accordingly important for further understanding of climate change. As part of the MERLIN climate mission, researchers from Aachen are developing a robust LIDAR system. This will eventually measure the methane concentration in the atmosphere on board a satellite.

It will send laser beams into the atmosphere day and night and calculate the methane distribution from the backscattered signals. Unlike conventional methane measurements with optical spectrometers, which require solar radiation, MERLIN-LIDAR can also measure values on the night side of the Earth. It can also be used to make measurements in small-scale cloud gaps. Accordingly, the laser must deliver full power over a temperature range of -30 to +50 °C. Special mounting technologies have been developed at the Fraunhofer ILT for this purpose, which are now also being applied to other satellite projects.

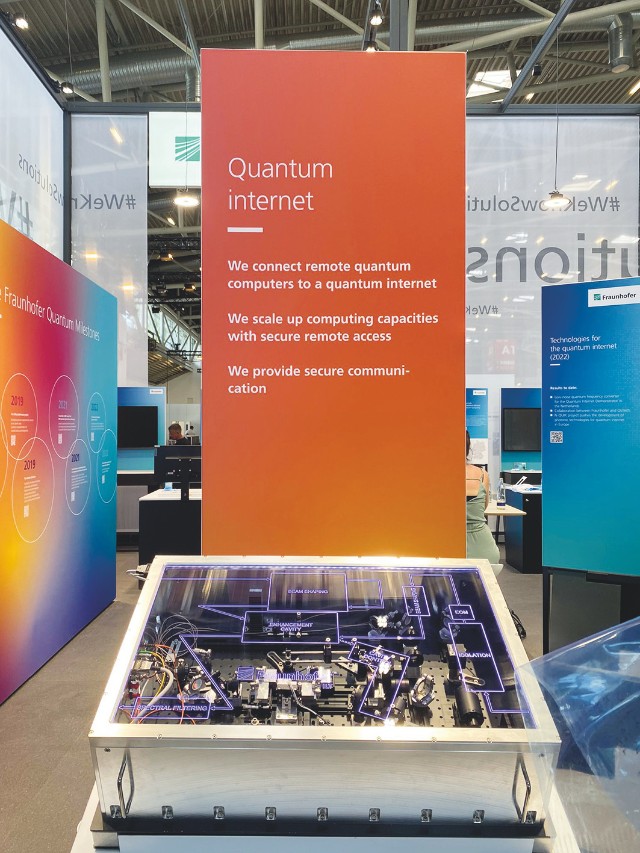

Quantum frequency converter for the quantum internet

Systems for the quantum internet are currently being developed in various funded projects. They are intended to enable tap-proof communication, and later also the networking of quantum computers. Communication via the quantum internet involves the transmission of individual photons generated in special light sources.

There is one problem with this: The light sources mostly operate in the visible spectral range, but the transmission fibers have their lowest losses in the near-infrared. In collaboration with QuTech – a joint research facility of Delft University of Technology and the Dutch Organization for Applied Scientific Research TNO – a team from Fraunhofer ILT has developed a quantum frequency converter (QFC) that solves the problem. It is now in use in Delft, where three different nodes are interconnected to form the first quantum information network.

An efficiency of around 50 percent (fiber in/fiber out) and ultra-low noise of 2 Hz/pm have already been measured on the QFC. The QFC can now be used in Aachen to test various components for the construction of quantum networks. As part of the N-Quik funding project, partners from industry and academia can thus develop new products and applications and tap the full potential of distributed quantum computing.

Coating and machining in one operation

High-strength protective coatings can withstand a lot. However, the better they protect, the more difficult they are to machine. A new process developed at Fraunhofer ILT solves this issue. Two manufacturing processes are combined for this purpose: The coating is applied using extreme high-speed laser material deposition (EHLA) and simultaneously processed mechanically. The coating is still hot at this point and, therefore, much easier to machine.

The process is called Simultaneous Machining and Coating (SMaC) and saves significant time, energy and material. “With SMaC, we can apply corrosion- and wear-resistant coatings economically. We achieve very high surface qualities in less time and with potentially longer tool life than with the usual sequential processing,” explains Viktor Glushych, head of the Coating LMD and Heat Treatment group at Fraunhofer ILT. Depending on the requirements profile and coating material, the processing time can be reduced by more than 60 percent.

The process can be applied very broadly, for the energy industry and the entire mobility sector all the way to the chemical and mining industries. Wherever highly loaded, rotationally symmetrical components are used, SMaC ensures savings in important resources.

Laser scanner with 90 percent less construction volume

Laser scanners are actually already quite optimized assemblies. Nevertheless, a team at Fraunhofer ILT has succeeded in achieving significantly smaller sizes by fusing the scanner drive and mirror substrate. The planar Galvo scanner saves up to 90 percent in construction volume compared to conventional systems.

The particularly compact design of just 50 cm³ also saves a great deal of weight, which opens up a whole range of possibilities for its application. For example, hand-guided systems can become even lighter, or several scanners can be used side by side in one processing head. This mini scanner uses commercially available, model-based control electronics, a simplicity that enables users to integrate it into existing machines using standardized communication protocols.

CAPS: High-power lasers for secondary sources

Beam times at the PETRA III beamlines at the German Electron Synchrotron (DESY) in Hamburg are usually overbooked. PETRA III produces brilliant short-pulsed X-ray radiation. This radiation is used to investigate welding processes on battery packs, for example, as well as molecular biological samples. For many of these measurements (or even radiation therapies), a decentralized solution would be a great simplification.

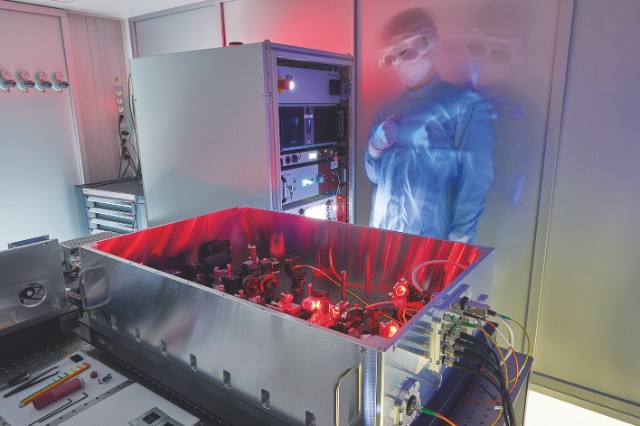

Among other things, several teams from the Fraunhofer-Gesellschaft are now working on this. In the Fraunhofer Cluster of Excellence Advanced Photon Sources CAPS, 21 Fraunhofer institutes have joined forces to develop new high-power lasers for ultrashort pulses. These lasers with kW outputs can already be booked in application laboratories in Jena (Fraunhofer IOF) and Aachen (Fraunhofer ILT). Thanks to a newly developed multipass compressor cell, the pulses of the kW lasers can be compressed to below 20 fs. The compressed pulses of the kW lasers can thus be converted into X-ray, terahertz, or MIR radiation, opening the way to decentralized secondary sources (i.e. sources of secondary radiation).

The next LASER World of PHOTONICS will be held in Munich, Germany, from June 24 to 27, 2025.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.