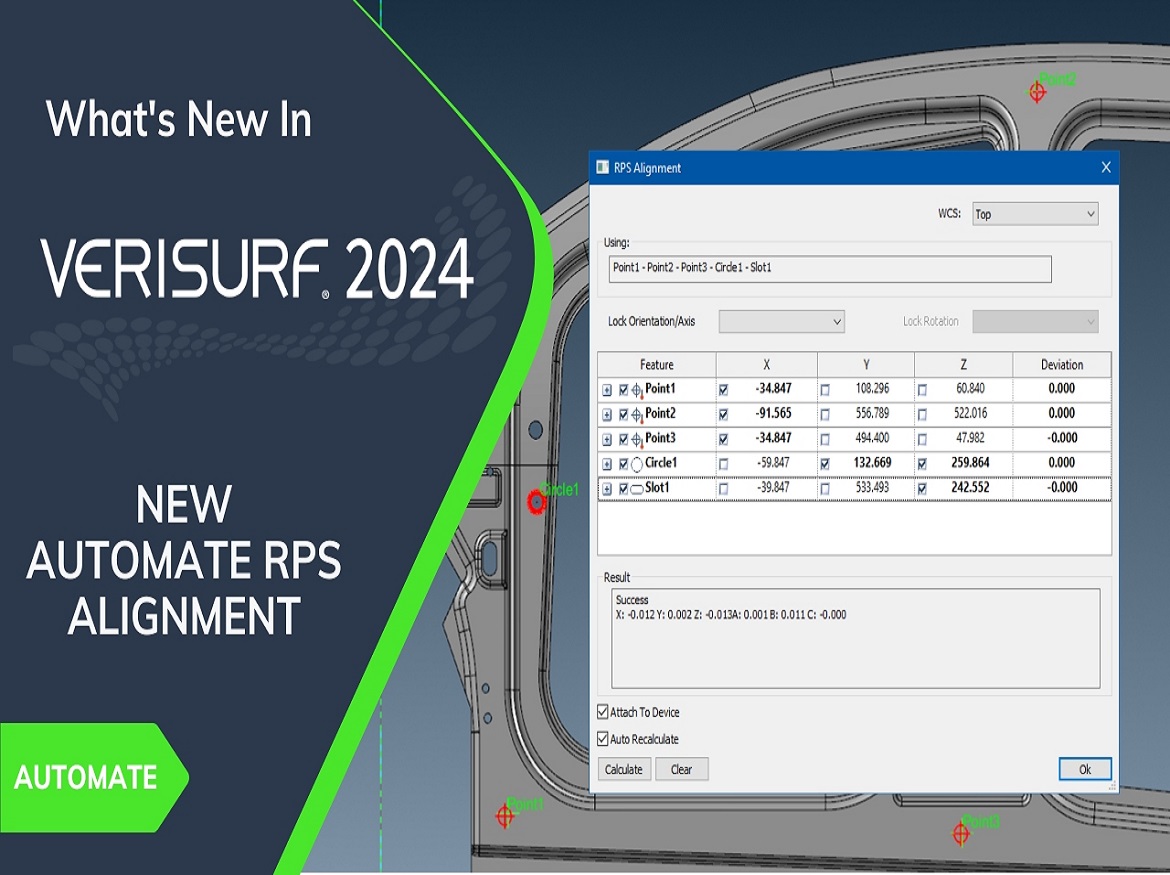

Verisurf Software, Inc. announces new RPS Alignment (RPS=Reference Point System) functionality added to its popular 3D metrology software. This new alignment capability was a popular request from Verisurf customers and is essential for automotive manufacturers to ensure precise alignment throughout the manufacturing process. With the new Verisurf RPS Alignment, aligning parts to CAD using defined reference points is faster and more efficient than ever. Verisurf RPS Alignment seamlessly connects measurements to defined reference points with precise control, streamlining the quality verification workflow.

RPS alignments play a critical role in industries like automotive, stamping, aircraft engines, and power generation, ensuring precise alignment of points and features on different part types to defined reference points. Verisurf RPS Alignment unites the powerful capabilities of Auto Align and Feature Align within the software. This innovative integration furthers Verisurf’s commitment and dedication to industry support, automation, and process improvement.

“At Verisurf, we are dedicated to improving quality and efficiency in measurement, inspection, reverse engineering, and tool building. Our software solution incorporates intelligent workflows, with value-added productivity tools like RPS Alignment, that boost quality and throughput,” stated Nick Merrell, Executive Vice President of Verisurf Software, Inc.

Verisurf’s RPS Alignment enables users to align parts effortlessly using measured points, features, and surface points. This versatility allows for easy alignment to virtually any datum scheme, facilitating effective planning and execution of alignment procedures while reducing errors and enhancing overall efficiency.

Verisurf is the only measurement, reverse engineering, and inspection software built on a full-featured 3D CAD/CAM platform with intelligent Model-Based Definition (MBD). This ensures data integrity and enables users to perform metrology workflows in a seamless CAD environment while maintaining model-based digital continuity. Verisurf software is compatible with all CAD file formats, and the Verisurf Device Interface (VDI) communicates with and operates all 3D measurement devices for universal compatibility. Verisurf’s modular design enables users to quickly shift from reverse engineering to inspection to tool building, efficiently capturing and processing measurement data for all 3D metrology applications with repeatable process control across the manufacturing enterprise.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.