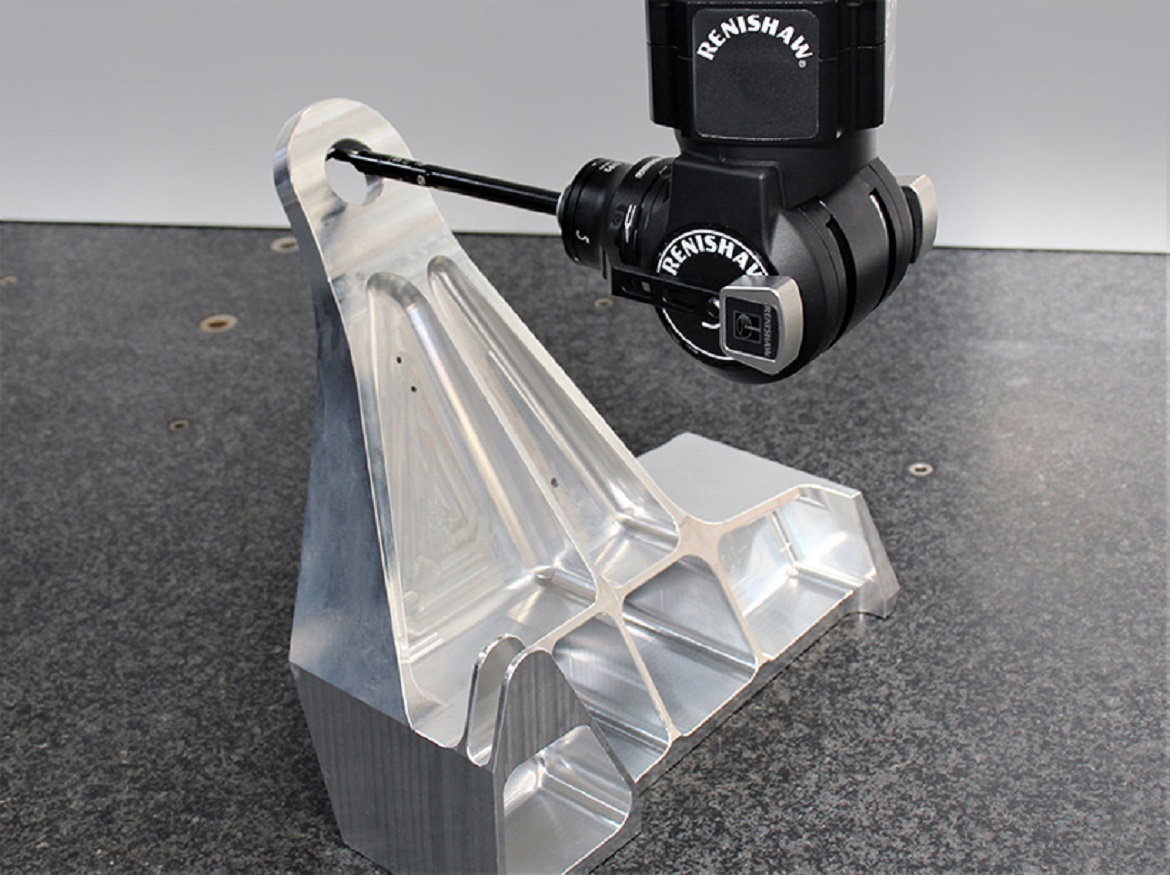

Surface Finish Range 6.3 μm to 0.05 μm Using Renishaw® REVO® SFP2 Probe

For CNC CMMs fitted with Renishaw REVO SFP2 (Surface Finish Probe), Verisurf Software, Inc. has announced the release of a surface finish measurement probe and reporting solution.

The soon-to-be-available Verisurf 2024 includes the surface finish measurement capability. Verisurf CMM programming can provide defined surface finish/roughness evaluation from 6.3 m to 0.05 m (250 into 2 in) Ra with results added to automated quality reporting using direct output from the Renishaw REVO SFP2 probe. Verisurf’s support for Renishaw REVO’s multi-sensor 5-axis measurement system makes this possible. The basic Verisurf CMM inspection program incorporates automatic probe switching depending on the inspection plan, which completely integrates surface finish measurement, minimizes inspection turnaround time, and eliminates CMM downtime.

With a 2, 5, or 10-micron radius diamond stylus tip, the REVO SFP2 can operate on a range of surfaces, including bores as small as 5mm (.196″), and it can output Ra, RMS, and raw data for additional analysis and reporting. When used in conjunction with Verisurf, the solution offers thorough and accurate data that can be compared to a standard 3D CAD model to allow operators to decide on the acceptability and quality of a component.

Through the Verisurf Device Interface (VDI), which allows two-way communications with practically all sensor kinds and manufacturers, Verisurf operates CNC CMMs equipped with Renishaw. The CMM is operated by the VDI, which also gathers measurement data for processing and analysis.

“We want to ensure that customers get the greatest value possible from their CMM investment. Automated reporting makes it possible to assess surface finish/roughness as part of a comprehensive inspection plan, and we are thrilled to be at the cutting edge of this technology. Many customers can decrease or perhaps do away with the requirement for specialized optical and stylus profilometers, depending on the application, according to Nick Merrell, executive vice president of Verisurf Software, Inc.

The only measuring, reverse engineering, and inspection software with intelligent Model-Based Definition (MBD) is Verisurf, which is developed on a full-featured 3D CAD/CAM platform. This maintains model-based digital continuity while ensuring data integrity and enabling users to carry out metrology processes in a seamless CAD environment. For complete interoperability, Verisurf software works with all CAD file types, and the Verisurf Device Interface (VDI) interacts with and controls all programmable and portable CMMs. By swiftly recording and processing measurement data for real-world metrology applications with repeatable process control throughout the manufacturing business, users of the program can quickly switch from reverse engineering to inspection to tool development.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.