Verisurf Programming, Inc. declares support for the Renishaw RUP1 (REVO® Ultrasonic Test), giving an ultrasonic thickness examining answer for computerizing the estimation and revealing of thickness necessities.

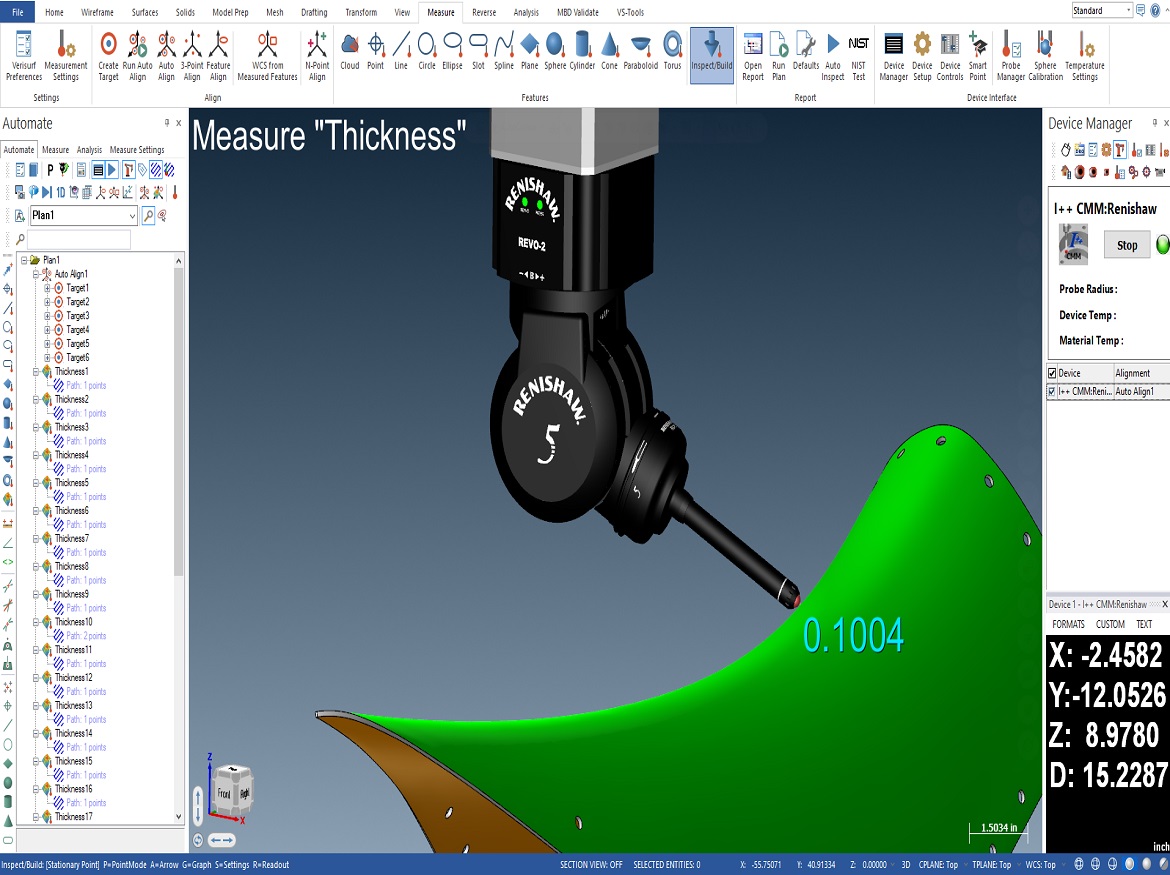

Support for the RUP1 will be highlighted in the impending Verisurf 2024 delivery. Ultrasonic thickness measurements are now a part of Verisurf Inspection Plans thanks to the powerful Dynamic Surface Points tool. A graphical balloon is used to store and display these measurements, presenting the recipients of the report with an easy-to-read thickness map of the inspected component. With the RUP1, thickness assessment is workable for regular metal parts going from 1mm (0.039″) to 20mm (0.787″) in thickness, with a precision of 0.01mm (0.0004″) on equal surfaces and 0.100mm 0(.0039″) on wedged surfaces with a point of up to 10 degrees.

Verisurf Programming works with Renishaw-prepared CNC CMMs through the Verisurf Gadget Point of Interaction (VDI), working with consistent correspondence with an extensive variety of 3D estimation gadgets. The VDI enables clients to choose their favored gadgets while offering a normalized arrangement that supports planning, tolerancing, approval, machining, gathering, estimation, review arranging, revealing, investigation, and figuring out.

“Verisurf has supported Renishaw-equipped CMMs and Renishaw products for a long time, and our team is still committed to continuously adding value through our software solutions, manufacturing knowledge, and engineering expertise. Nick Merrell, Executive Vice President of Verisurf Software, Inc., stated, “Verisurf solutions are renowned for their user-friendliness, stability, flexibility, and intelligent workflows, which enhance efficiency, quality, and throughput.” Verisurf is the only measurement, reverse engineering, and inspection software built on a full-featured 3D CAD/CAM platform with intelligent Model-Based Definition (MBD). Users can carry out metrology workflows in a seamless CAD environment while still maintaining model-based digital continuity thanks to this, which guarantees the integrity of the data. The Verisurf Device Interface (VDI) communicates with all 3D measurement devices for universal compatibility, and the Verisurf software is compatible with all CAD file formats. Verisurf’s secluded plan empowers clients to rapidly move from figuring out to investigation to instrument building, proficiently catching and handling estimation information for all 3D metrology applications with repeatable interaction control across the assembling undertaking.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.