Robust Quality Control at the Edge with High ROI

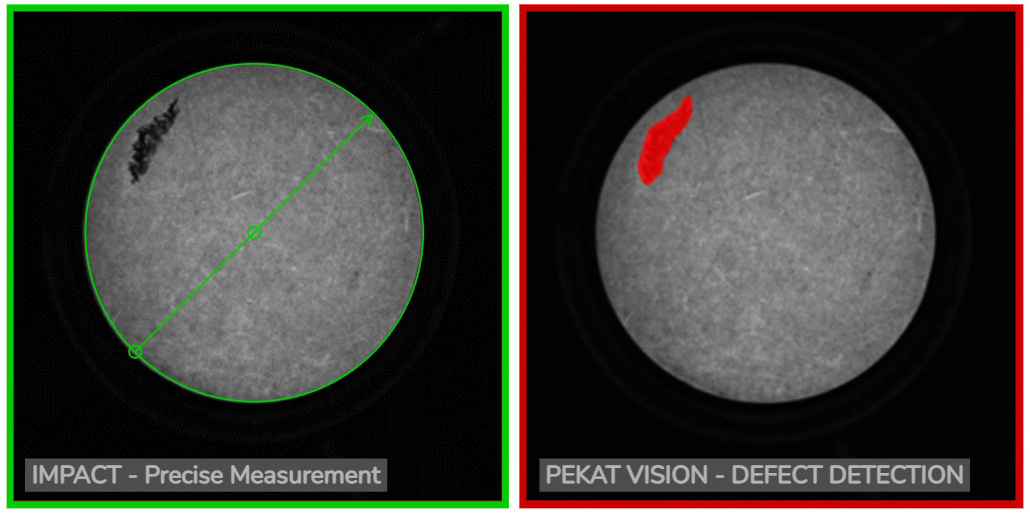

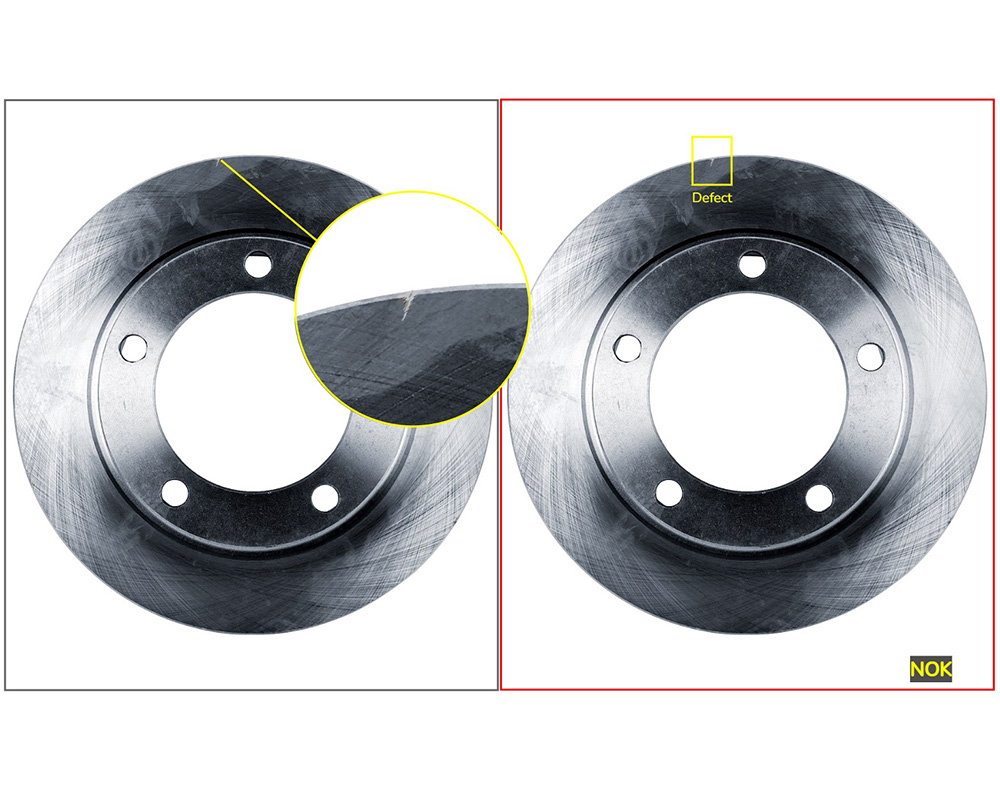

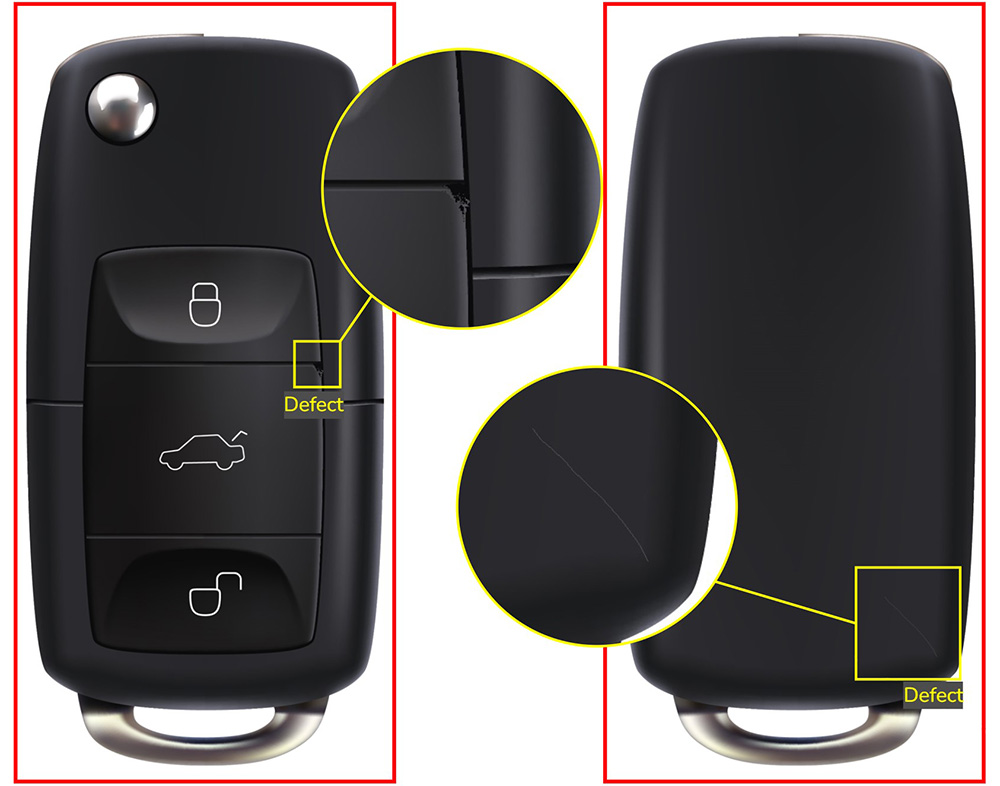

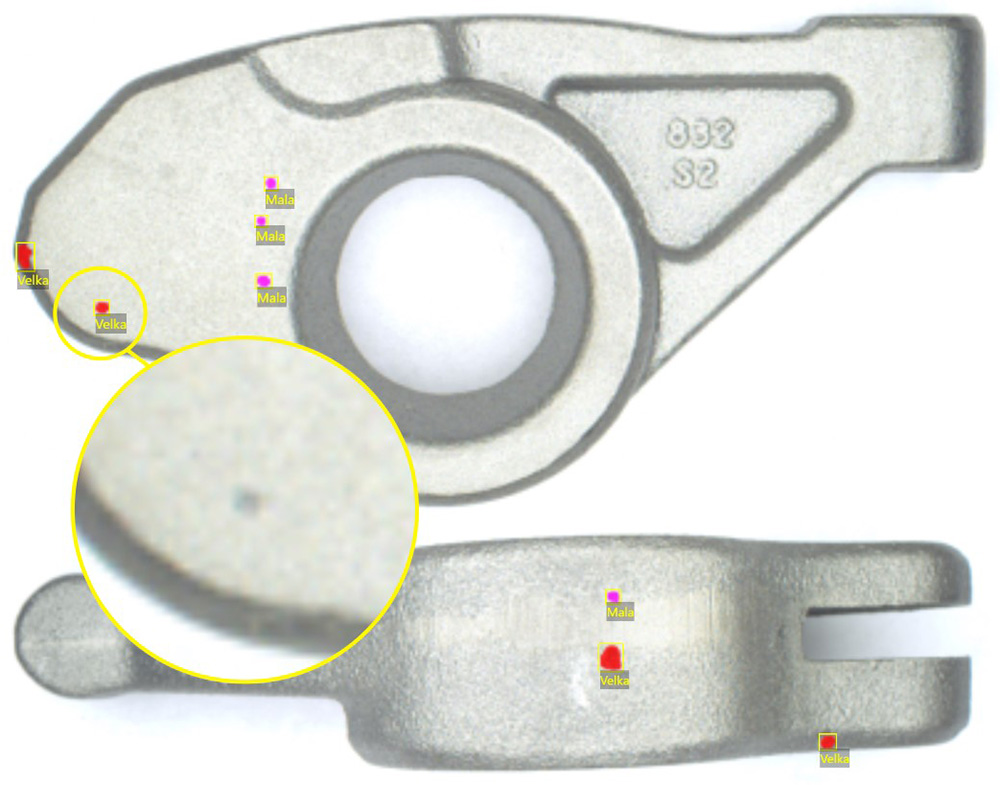

The Fusion of Deep-learning and Rule-based Methods

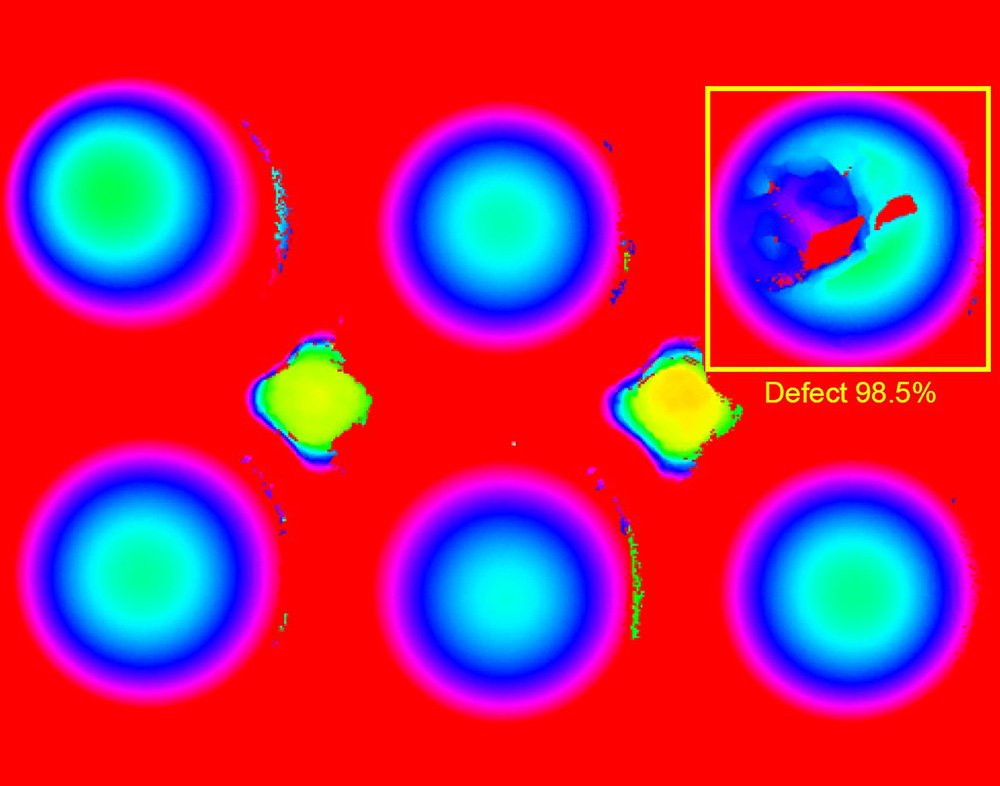

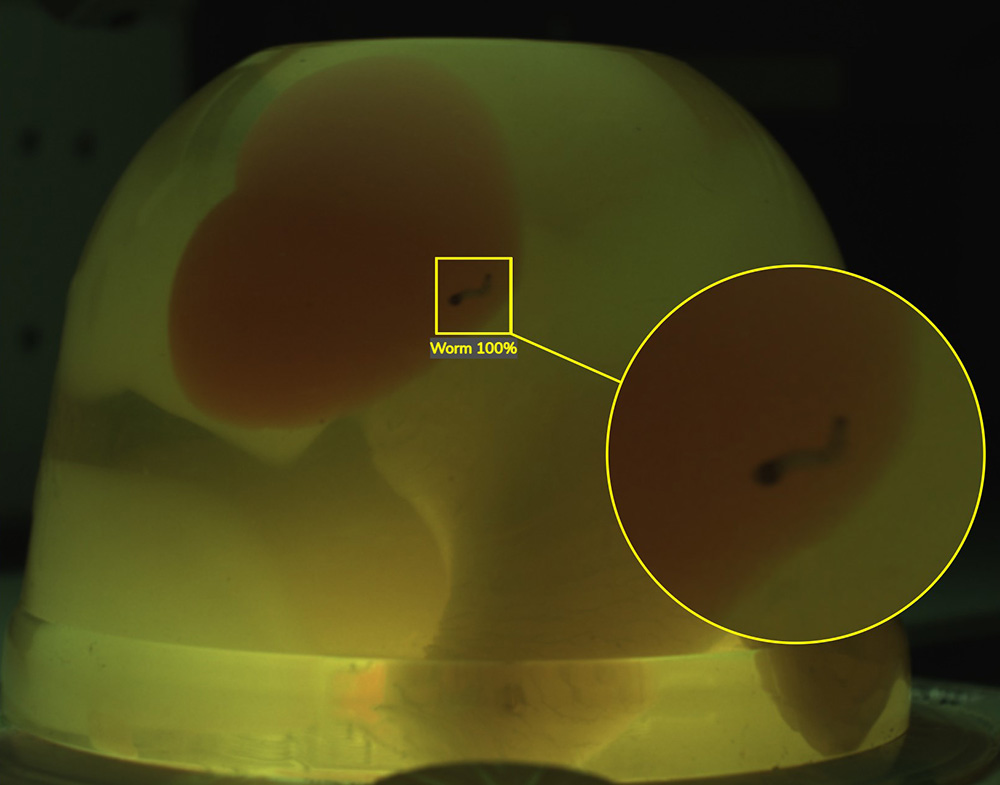

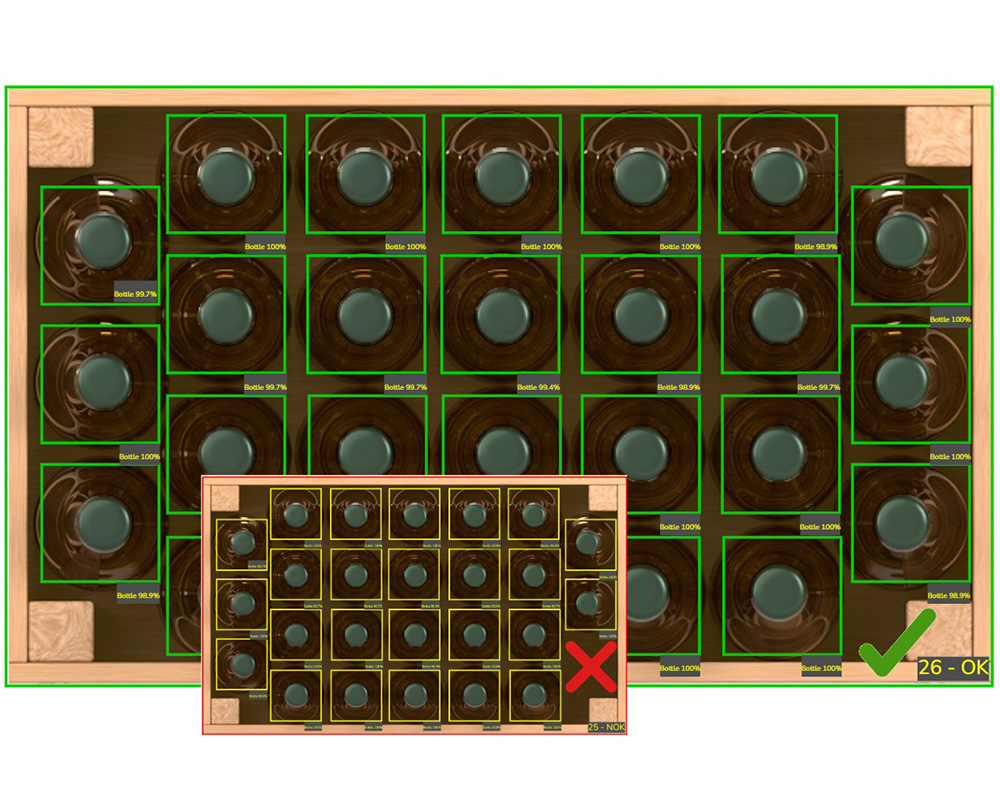

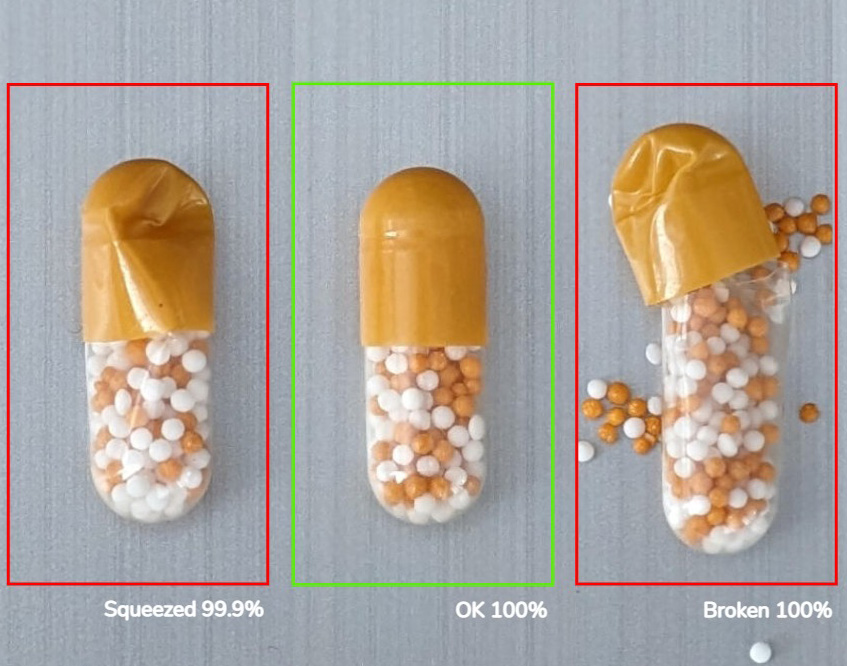

At the heart of our Vision Processor lies a dynamic synergy between deep-learning and rule-based methods, providing a comprehensive solution for industrial automation. Traditional rule-based methods excel in image pre-processing, precise measurement, 1D/2D code reading, color analysis, and more. Meanwhile, our cutting-edge deep-learning software easily identifies random, unpredictable defects, detects and classifies objects, inspect surfaces, or reads and verifies text on a variety of diverse materials. These two approaches, though distinct, work harmoniously within our vision processor, addressing the diverse needs of industrial automation.

Solution for Multiple Industries with Seamless Integration

The MX-G2000 Vision Processor ensure simple deployment in diverse production lines. It’s superior processing power, sufficient for the most demanding tasks, and the pre-installed PEKAT VISION Suite guarantee reliable visual inspections and quality assurances for diverse applications across multiple industries. It’s been specifically designed for the harsh industrial environment.

The Latest Computing Technology

Designed with the requirements of future manufacturing environments in mind, the MX-G2000 Vision Processor integrates NVIDIA® RTX A4000 graphics and 12th generation Intel® i5 processor to deliver the best computing power even for the most demanding industrial applications. From training your models in a matter of seconds to searching for defects in large, high-resolution images, or creating complex applications with hundreds of different tools, you will appreciate the agility of the Vision Processor.

| Processor | Intel Core i5-12500TE (Alder Lake) 1.9~4.3 GHz 6-core 35W |

| Memory (RAM) | 32 GB SO-DIMM DDR4 2666 |

| Primary Storage | 512 GB M.2 NVMe SSD |

| Graphic Card | Nvidia RTX A4000 GPU -16GB (incl. Aux PCIe Power Board & Cables) |

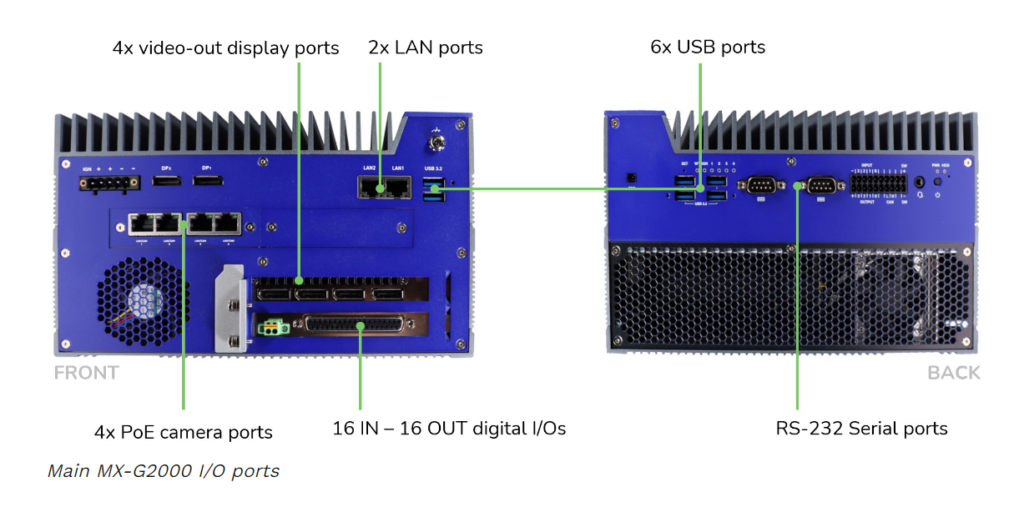

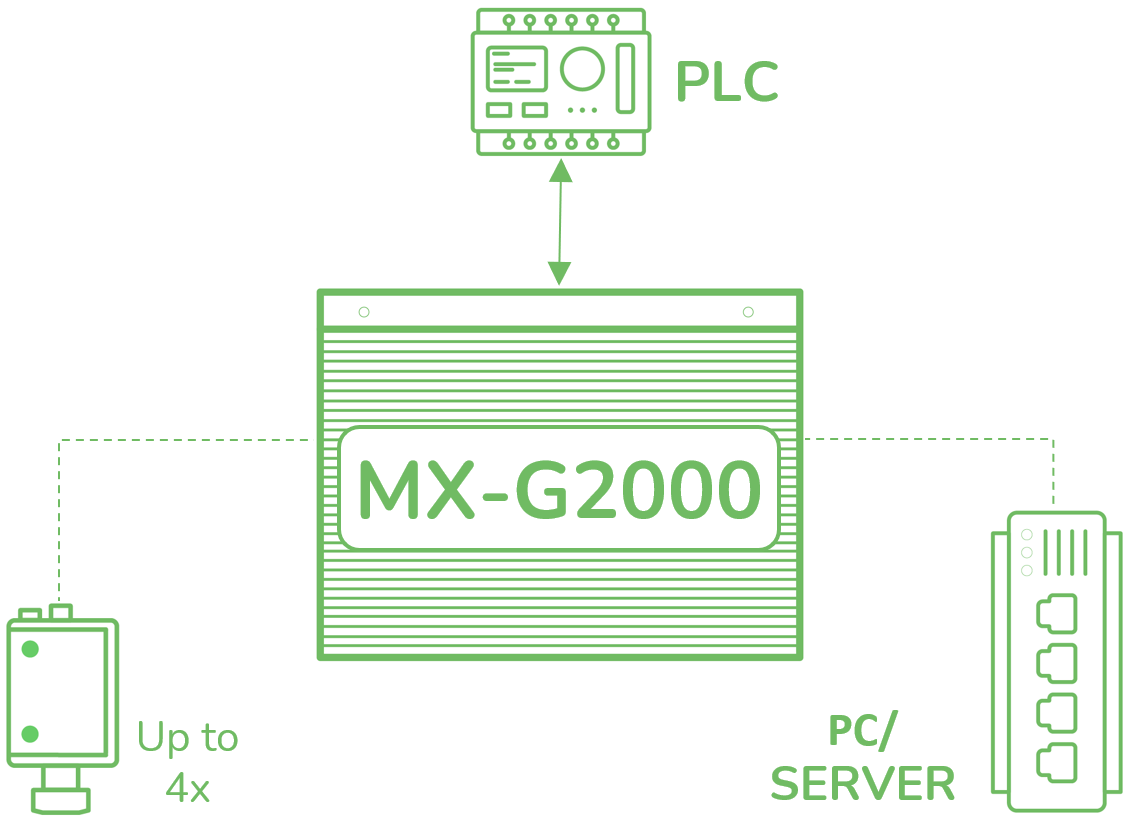

Extensive Communication and Integration Capabilities

The MX-G2000 Vision Processor delivers a flexible and versatile solution for many industrial applications. Its selection of legacy and new ports will ensure compatibility with the vast majority of equipment used in industrial automation.

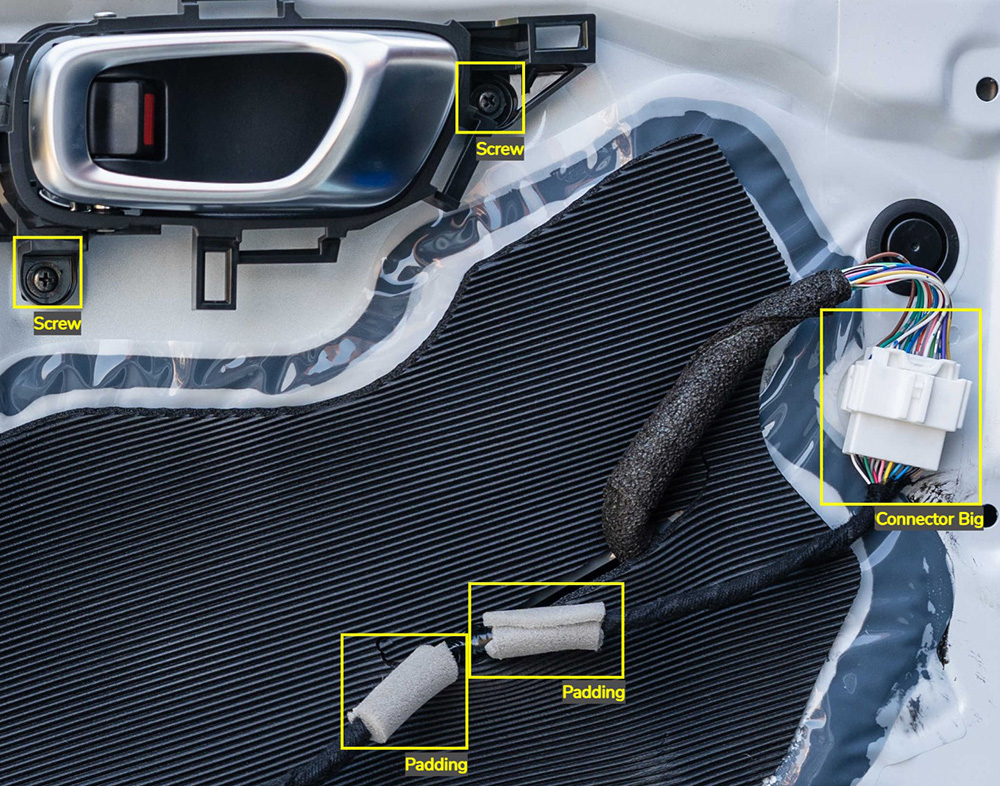

Example of MX-G2000 wiring