A Joint Technology Development Agreement between Waygate Technologies and GE Aerospace will advance inspection solutions for commercial aircraft engines.

To help Maintenance, Repair, and Operations (MRO) providers, collaboration is focused on modernizing and developing cutting-edge solutions for remote visual inspection with artificial intelligence software.

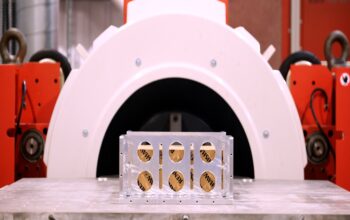

The market leader in non-destructive testing (NDT) solutions for industrial inspection, Waygate Technologies, a Baker Hughes company, and GE Aerospace today announced the signing of a joint technology development agreement (JTDA) to create software and hardware inspection solutions for commercial aircraft engines.

The agreement aims to reduce expenses for repair, Repair, and Operations (MRO) shops and on-wing repair providers while advancing and improving video borescope inspection efficiency, accuracy, and quality. Advanced analytics-focused technology solutions will also be pursued by Waygate Technologies and GE Aerospace.

Since there are so many potential unserviceable situations or faults, current borescope examination can be labor-intensive and necessitate highly experienced manual visual inspection to spot nonconforming indicators. By providing repeatable, trustworthy information to inspectors, advanced analytics can speed up inspection cycles and increase inspection uniformity.

According to Michael Domke, General Manager Visual at Waygate Technologies, “This agreement is an opportunity to partner and work together with GE Aerospace, who has a great deal of experience as an engine OEM and a maintenance provider.” “When you combine their capacity with Waygate Technologies’ experience offering cutting-edge borescope systems, sophisticated 3D measurement, and software technologies tied to digital inspection data management, it makes for a fantastic marriage. We are eager to keep up our efforts and support for the aerospace industry’s transition because it can have a significant beneficial influence on our mutual customer base and is essential to our overall business plan.

Engine-level inspection is a highly specialized job that is becoming more and more necessary due to the development of MRO demand, according to Nicole Tibbetts, Chief Manufacturing Engineer for MRO at GE Aerospace. “We are enthusiastic about our partnership with Waygate Technologies and committed to finding solutions that will significantly improve the quality, cost, and turnaround time of engine work scopes and on-wing maintenance,” the company said.

Click on the following link Metrologically Speaking to read more such news about the Metrology Industry.