Portable coordinate measuring devices known as “articulated measuring arms” are made to take precise measurements using both a 3D scanner and a probing system (contact measurement) (contactless measurement). They are also known as portable CMMs and multi-joint arms. They are usable by everybody due to their accessibility and simplicity.

Because of their high mobility, measuring arms may be relocated with ease and employed in a variety of settings, including design studios, metrology labs, and workshops. They are incorporated into the design and manufacturing processes without causing any disruptions and get as close as feasible to the parts that need to be measured. For a wide range of applications, including quality control, 3D inspection, reverse engineering, maintenance, and fast prototyping, measuring arms offer significant versatility.

How does a measuring arm work?

Calculating the position of the end of the arm in real time.

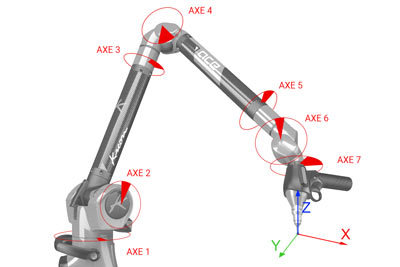

The design of a measuring arm is based on the human arm, with segments like the forearm and arm and axes of rotation that are comparable to joints like the shoulder, elbow, and wrist.

It is feasible to ascertain the precise location of the arm’s tip in space in real time by accounting for the geometric lengths of the components that make up the arm and the angular positions returned by the encoders located in each axis (in the form of 3 XYZ coordinates). An crucial consideration for the measuring arm’s ultimate accuracy is the selection of encoders and their resolution.

Obtaining the measurement accuracy.

A calibration method is utilized to precisely characterize the arm’s whole geometry.

After that, validation tests are performed to confirm this calibration and ensure the accuracy of the measurements taken by the user.

The international standard ISO 10360-12, which outlines these testing, is complied with by Kreon weapons. As a result, they may be utilized confidently to probe geometries with demanding precision requirements as well as quickly scan and inspect component surfaces.

Impeccable measurements whatever the environment.

The arms are rigid and durable thanks to the use of suitable materials, like carbon and aluminum, while their small weight makes them portable. The portable CMM may be used anywhere in the business and adjusts to various indoor and outdoor situations while keeping constant accuracy by accounting for temperature changes.

The wireless connection and inbuilt battery release the measuring arms from the restrictions of cords and make it easier to use and transport them.

What is the purpose of a measuring arm?

Measuring arms make it possible to inspect small, large, and complex items effectively.

Measuring arms are used in many industries. They are primarily used for quality control, 3D inspection, and reverse engineering in the aerospace and automotive industries, as well as more broadly in the industrial sector.

So, an operator may utilize it too, for instance, use GD&T (Geometric Dimensioning and Tolerancing) with the aid of metrology software to check the dimensions and tolerances of a part.

One of the most popular uses is CAD comparison using scanned data. This entails contrasting a physical part’s flaws or deformation with its conceptual CAD model. Color mapping is utilized to vividly depict potential discrepancies and so validate or invalidate the part’s conformance.

On the other hand, reverse engineering is frequently employed when a part’s CAD model is unavailable. Using a 3D scanner, a part can be completely digitalized, allowing for the creation of the CAD model, which is now crucial to the production process.

What configuration for a measuring arm?

Choosing between versions with 6 or 7 axes of rotation.

There could be 6 or 7 axes of rotation on a measuring arm. There was only a 6-axis version available at first. It was only meant for probing purposes and was quite accurate.

A new axis was introduced with the introduction of specific attachments, particularly 3D scanners. It has a handle, which gives it the extra mobility required to maneuver the scanner in space with skill. This 7-axis arm is less accurate because of the extra axis, but it is more adaptable because it can be used for both probing and scanning.

When probing particular holes, the handle that controls and directs the scanner can occasionally be awkward and difficult to use. Hence, some variants, like the brand-new Onyx arm, have a detachable handle.

Choosing the right size of measuring arm.

The measuring volume, also known as the arm’s size, roughly equates to the diameter of a sphere that the arm can measure. It is directly correlated with the arm’s tube length. This characteristic also influences an arm’s accuracy, with a smaller arm being more accurate. The greatest accessible distance and the measurement volume are distinguished from one another (see drawings).

The size range of Kreon’s 6 and 7-axis arms, which extend from 2 to 5 meters, is extensive.

So, finding the best measuring arm requires striking a balance between the needed accuracy and the desired work volume.

Click on the following link Metrologically Speaking to read more such blogs about the Metrology Industry.