ZEISS offers you numerous software options for the software for special applications and measuring tasks to expand ZEISS CALYPSO. Would you like to measure curve-related characteristics? Or simply create inspection plans offline? Then use one or more options. You can purchase these in addition to ZEISS CALYPSO to adapt the software to your individual measurement requirements.

ZEISS CALYPSO Planner

With ZEISS CALYPSO planner, measurement plans can be created offline. This way, your measuring machine is not tied up and ready for other tasks.

With the software option, you have the ability to create complete CNC measurement plans on a workstation remote from the CMM. Your advantage: Measurement plans created with CALYPSO planner can be opened and executed at any time directly on the CMM.

The benefit: The CMM is not blocked for programming and can be used for measuring. The overall process throughput is thus retained and your productivity is increased.

ZEISS CALYPSO simulation

ZEISS CALYPSO simulation software option makes it possible to simulate the complete measuring program, including the CMM travel paths. Measurement plans can thus be optimized without CMM connection. The visualization on the CAD window helps users to identify whether the measurement sequence or stylus systems should be altered in order to achieve a better result in less time.

The CAD simulation includes the CMM environment and the workspace on the CMM. Critical situations, such as collisions, can be identified and eliminated up front.

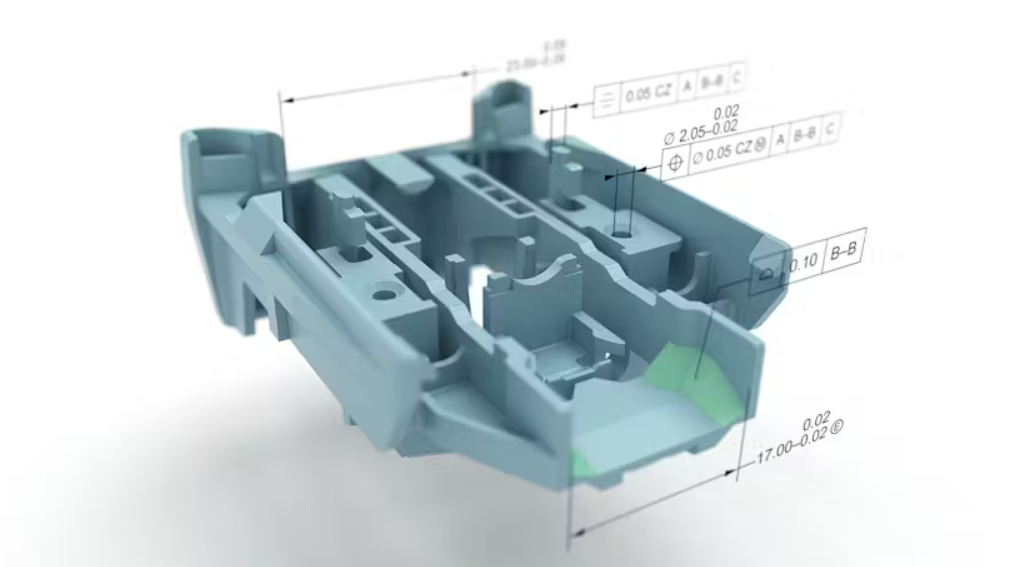

ZEISS CALYPSO freeform

ZEISS CALYPSO freeform is a software option for measuring, inspecting and analyzing workpieces with non-standard 3D geometries and performing surface analysis.

The software option calculates the distance between measurement points and the CAD model. The measurement results can be used to show the differences between the nominal and actual surfaces. ZEISS CALYPSO offers an improved mathematical algorithm for even better performance. The measurement results are now available 20 times faster than before.

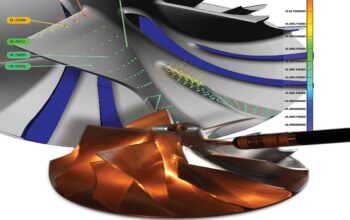

ZEISS CALYPSO curve

ZEISS CALYPSO curve enables measurements and analyses of 2D curves (intersection on one plane), 3D curves (intersection on a cylinder or freeform surface), lift curves, known and unknown contours and symmetry curves. Numerous curve-related characteristics can also be reported, including curve slope, curve stroke, curve distance, curve expansion, curve length, surface area, speed and acceleration.

ZEISS CALYPSO PCM

ZEISS CALYPSO PCM (Parameter-Coded Measurement) significantly decreases the amount of time needed to measure workpieces of the same part family.

The software option is ideal for manufacturers that produce workpieces similar in shape, function, and production process, but only differ by a few dimensions. With CALYPSO PCM there is no need for creating a measurement plan for each individual workpiece in a family anymore. With this, you can save time in the overall programming process for a family of workpieces.

ZEISS CALYPSO roughness

ZEISS CALYPSO roughness is a software option for determining and graphically displaying roughness parameters as a function of selected parameters.

The complete integration of the roughness measurement ensures that you capture all the characteristics of your component in one measurement run – in full compliance with the standards.