3D X-Ray Measurements for Quality Assurance

This content was originally written and published by the Zeiss team on their website. Reproduced here from https://www.zeiss.co.in/metrology/products/systems/computed-tomography/metrotom.html#4

Industrial Computed Tomography with ZEISS METROTOM

With an industrial computed tomography system from ZEISS, you can successfully perform measuring and inspection jobs yourself with only one X-ray scan. The standard acceptance test, precision engineering, and the sophisticated calibration process ensure the traceability of the system. Linear guideways and a rotary table meet customers’ highest demands for precision.

New ZEISS METROTOM 1500 in its third generation

Future-proof quality control – today

The ZEISS METROTOM family has been offering reliable CT technology for quality control for twelve years. The third generation of the computed tomography (CT) system ZEISS METROTOM 1500 provides the best proof that advanced and reliable X-ray technology is no longer a vision of the future. You can future-proof your quality control – today.

Measure and inspect larger parts

The third generation of ZEISS METROTOM 1500 allows measurements of larger parts, thanks to an extended measuring volume.

More comfortable and safe operation

The front door, which allows the operator to enter the system and use it as a service access point, makes loading of larger and heavier components more convenient. This allows the user to perform CT measurements easily, safely, and accurately.

Compact footprint

For transport, installation, maintenance or the consumed space in the customer’s lab -– the smaller the system, the better. The design of the cabin of ZEISS’ largest industrial CT system was entirely devoted to the efficient use of space.

See more.

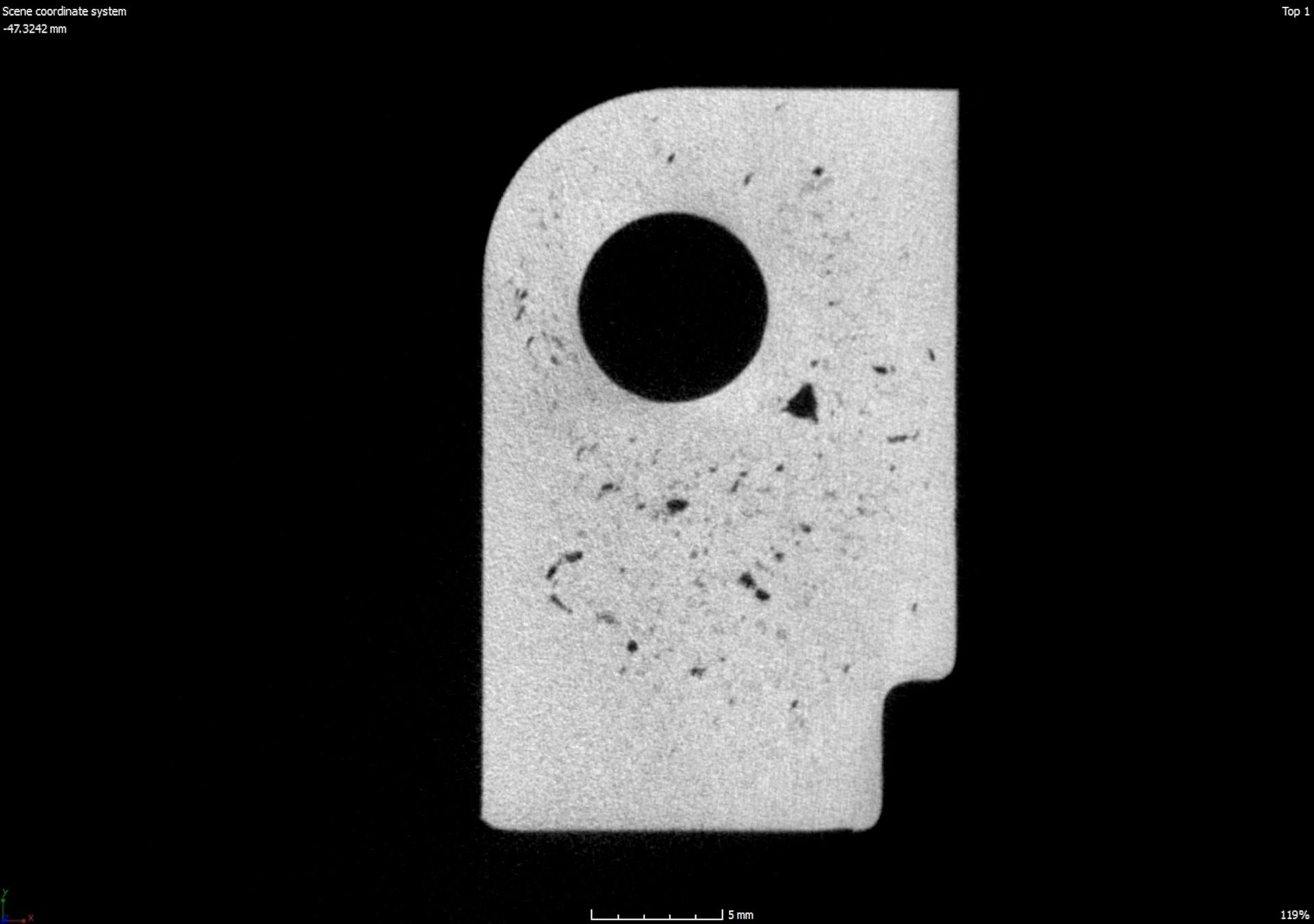

In the third generation, a new 3k detector generates 3D volume data sets with higher resolution, i.e. more voxels permitting the detection of smaller defects.

Scan faster.

The scan time can be reduced by up to 75% through different operation modes of the detector while achieving a comparable voxel size as with a 2k detector.

Perform easy measurements with ZEISS METROTOM

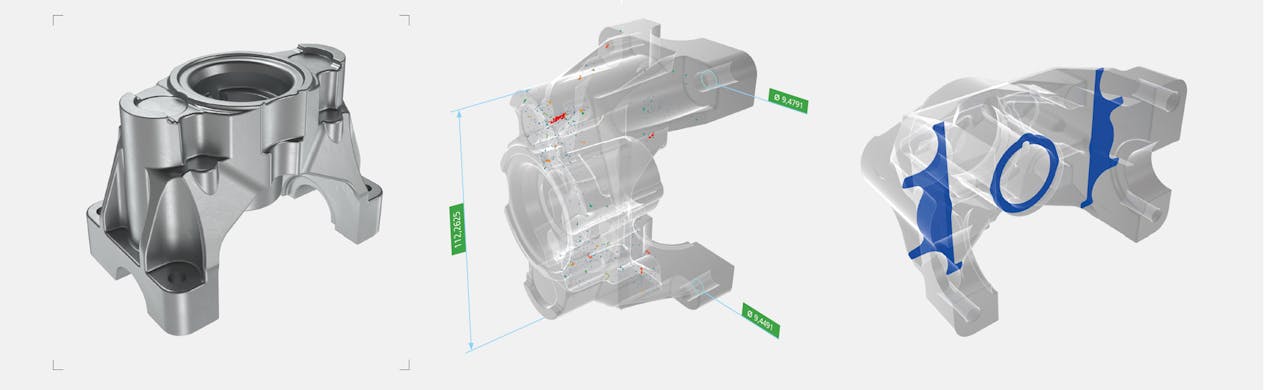

Measuring and inspecting complete components

The ZEISS METROTOM is an industrial computed tomography system for measuring and inspecting complete components made of plastic or light metal. With traditional measuring technology, hidden structures can only be inspected after the time- and cost-consuming process of destroying the component layer-by-layer.

Measure a lot of characteristics easily and precisely

With ZEISS METROTOM computed tomography system, numerous component characteristics are scanned in one run. The resulting measurements are precise and traceable. Unlike contact measuring methods, ZEISS METROTOM is significantly faster when capturing numerous measuring points.

Intuitive handling

Following a short training course on how to use the ZEISS METROTOM OS machine software, the operator is able to tomograph components and look into the interior of the component. With ZEISS CALYPSO and GOM Volume Inspect, you can evaluate the CT data. The last-mentioned allows you not only to solve measurement tasks but also to carry out defect analyses. With ZEISS PiWeb, the results can be merged quickly in a single measurement report.

Comprehensive CT data analysis in 3D

The easy-to-use and even for beginners suitable analysis software GOM Volume Inspect allows complete CT data analysis in 3D. Geometries, shrinkage holes, or internal structures and assemblies can be analyzed precisely. Even the smallest defects become visible through individual sectional images and can be automatically evaluated according to various criteria. You can also load volume data of several components into a project, perform trend analysis, and compare the analysis with CAD data. In this way, the quality of your component can be exactly determined and documented – and all this in just one software.

DAkkS calibration for increased confidence

Higher quality standards in the automotive, medical, or pharmaceutical industry often make it necessary to rely on accredited CT inspection procedures. These guarantee an objective, standard-compliant measurement of parts according to VDI/VDE 2630 part 1.3. DAkkS certification is accepted worldwide, which eliminates the costs for multiple assessments. Now the DAkkS calibration is also available for the computer tomographs of the ZEISS METROTOM 800 and 1500 series! Benefit from its advantages: save costs and create more trust for your customers.

To know more, please check Zeiss.

Wonderful article! We will be linking to this particularly great content on our website. Keep up the great writing. Deanna Lefty Celka

Hi there, after reading this awesome piece of writing i am as well delighted to share my knowledge here with friends. Salaidh Alex Jacoba