Innovative technology for speed and accuracy.

A precise, high-speed metrology and inspection system for processing complex geometries in just a fraction of time versus a traditional CMM.

By leveraging more than four decades of developing high precision automation and metrology solutions, DWFritz Metrology is now launching the next generation of high speed, non-contact metrology platforms.

ZeroTouch® ZTM-333 uses multiple non-contact sensors to simultaneously capture 3D dimensional data, creating a high precision point cloud to measure part dimensions in a few minutes, instead of longer cycle times like traditional coordinate measuring machines (CMMs). Setup and measurement also take only minutes. Part inspection planning replaces programming and takes hours instead of days, with intuitive drag and drop functionality.

ZeroTouch ZTM-333 is an innovative, multipurpose measurement platform that combines multiple sensor technologies with custom multispectral lighting and deep learning software in one footprint. ZeroTouch’s rugged industrial design offers the accuracy, precision and speed that manufacturers need to optimize inspection cycle time in production environments.

KEY BENEFITS

- One system captures multiple measurements simultaneously in a fraction of time versus a traditional CMM

- Easy creation of part inspection plans saves measurement times of different parts

- Micron-level precision non-contact metrology with high repeatability

- Ease of part placement reduces setup time per part

- In situ calibration improves repeatability

- Fast identification of production defects, enabling adjustment of upstream processes to reduce waste

- Highly configurable and optimized for each manufacturer’s specific application

KEY FEATURES

- Captures precision point cloud data to construct complex 3D profiles

- Advanced analytics integration with application-specific tools

- GD&T measurements, including complex geometries such as chamfers, knife edges, undercuts, and bores

- Defect detection capabilities

- Configurable metrology sensor bridge, including:

- Laser and chromatic confocal sensors

- High-resolution cameras with multispectral lighting

- Additional options include:

- Automatic part registration

- Barcode scanning that automatically loads the inspection part plan from MES

- Microenvironment for temperature control

- Automatic part load/unload robot integration

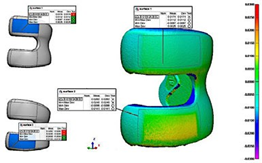

Measurement Profile of Knee Implant

Multisensor technology measures parts faster

Using application-based custom sensors, the system can capture millions of points per second, with variable data density levels, in just one scan. Multisensor Measurement of complex geometries such as bores, undercuts, and chamfers across a wide variety of materials enables precise inspection of even the most intricate parts with low GRR.

Planar air bearing design minimizes tolerance stack error

ZeroTouch ZTM-333’s unique planar air bearing design provides an extremely smooth, high-speed motion of precision stages, improving GRR. With this near zero-friction design, there’s no mechanical wear and performance remains consistent over time.

Advanced analytics integration

Through industry proven and recognized analytics software, parts can be analyzed by comparing point cloud scans with nominal CAD models and GD&T controls. Statistical process control (SPC) data can drive warnings to reduce variability and scrap.

Highly configurable control software

Working with MES, ZeroTouch ZTM-333 will store and obtain part inspection plans, as well as measurement data for every part, preserving data integrity. Menu driven, automated creation of part inspection plans can be launched easily by recalling the program from MES or via an optional barcode reader. Control software also ensures operator safety, disabling tool motion when enclosure panels are open.

KEY INDUSTRIES

Aerospace

- Impellers

- Turbine Blade

- Gears

- Shrouds

Diffusers

- Vanes/nozzles

- Compressor blades

- Blisks

Medical Devices

- Dental implants

- Medical implants (ocular, spinal, orthopedic)

- Surgical and general instruments

- Prosthesis

- Distractors (mandibular, cranial, osteo)

Precision Manufacturing

- Precision tools, die molds, and bearings

- Parts and assemblies with electropolished surface

- Machined parts with complex geometries

- Parts with sealing surface

Automotive

- Powertrain components

- Gears and sprockets

- Clutches

- Pistons

- Bearings

- Brake components

- Valve bodies

- Gasket surfaces

To know more, check DWFRITZ.