Andretti Autosport has announced that Applied Automation Technologies (AAT3D) will serve as the team’s official metrology solution. AAT3D began in 1987 as a CAD-based dimensional measurement software and developed into a global leader of software solutions for metrology, quality control and manufacturing systems.

“For over 30 years, Applied Automation Technologies (AAT3D) has been an industry leader in on-machine metrology to improve precision manufacturing processes and quality standards,” said Ray Karadayi, CEO, Applied Automation Technologies. “We are excited to partner with Andretti Autosport as a technical sponsor and provide our expertise. The Andretti name is legendary in autosport and we look forward to being a part of the team.”

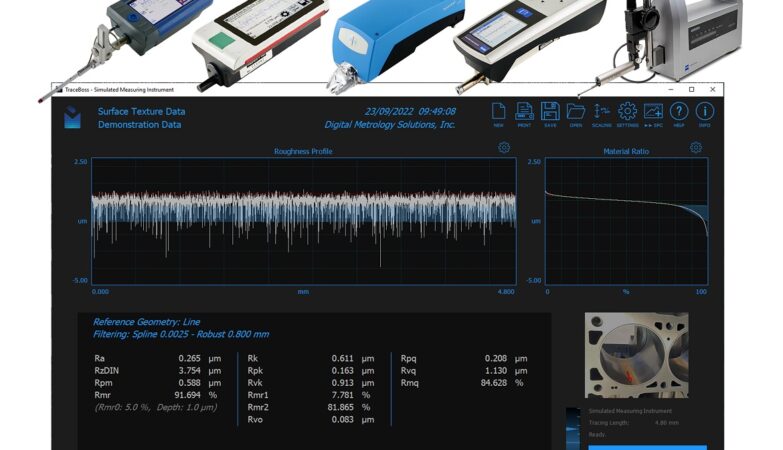

Over the years, AAT3D has been able to create on and offline programs for their software including the CAPPSNC software. AAT3D’s CAPPSNC software allows measurement programs the ability to be developed offline while directly running the program software on CNC machine tools. The AAT3D measurement software works with Andretti Autosport’s Siemens NX CAD software and DMG MORI machine tools, improving quality and efficiency in the manufacturing process. With the transition of dimensional inspection process to the CNC machine, a closed-loop feedback system is created allowing to yield higher accuracy, fewer defects and reduced post inspection time.

“We’re very excited to establish a relationship with Applied Automation Technologies,” said Scott Graves, Engineering Manager at Andretti Autosport. “Their innovative metrology automation software will help us achieve a new level with our manufacturing processes and bring better parts to the racetrack. AAT3D will be a valuable addition to our family of technical partners.”

Using AAT3D’s software amongst Andretti Autosport’s machinery will allow the team to focus on quality control in dimensional measurements and the overall machining process. As an independent software provider AAT has developed an extensive library of controller interfaces for both CMM and CNC machine-tool controllers. The company has pioneered machine tool metrology with closed loop metrology software since the 1990’s. AAT software allows the adaption and programming of any machine-tool as a CMM with integrated capability of providing real time feedback to the controller allowing adaptive manufacturing to be performed.

CAPPSNC provides capabilities to quickly develop measurement programs offline and run these programs directly on CNC machine tools in a similar fashion to a CMM.

Measurement results are used to adjust machining process parameters such as calculating precise work offsets, dynamic tool compensations and other critical data feedback in an automated process, together with providing complete part inspection and SPC reports without the need to take the part off the machine and to a CMM lab.

Using such closed-loop feedback to provide correction for the machining process allows the system to be self-adapting to factors that affect the machining process and the quality of products being machined.

For more information, visit www.aat3d.com.