The waviness of a tooth flank can cause unpleasant noises in the interior of a motor vehicle. Using high-resolution and area-based measurement technology, Honda has succeeded in isolating and quantifying the waviness from the roughness on a flank. By applying Focus-Variation and frequency analysis methods, the Research & Development team was able to identify and successfully reduce disturbing noises.

“The system we used before no longer met our requirements. With InfiniteFocus we measure faster and get much more meaningful information. We have become much more efficient!”

Naoto Syukushima, Powertrain Prototyping Department at Honda

Optimize manufacturing process of hypoid gears

Modern driving comfort and a high noise level in the interior of a car are a contradiction. For the automotive industry, this means to avoid NVH phenomena (“noise, vibration, harshness”). Disturbing noises may have their cause in a gearbox´s powertrain. Often, they can be traced back to the waviness on gear tooth flanks. This is why Honda uses an optical 3D measurement system to identify and measure the waviness on the flanks, enabling the global automotive manufacturer to optimize their manufacturing process of hypoid gears and, subsequently, to eliminate unwanted gear noise.

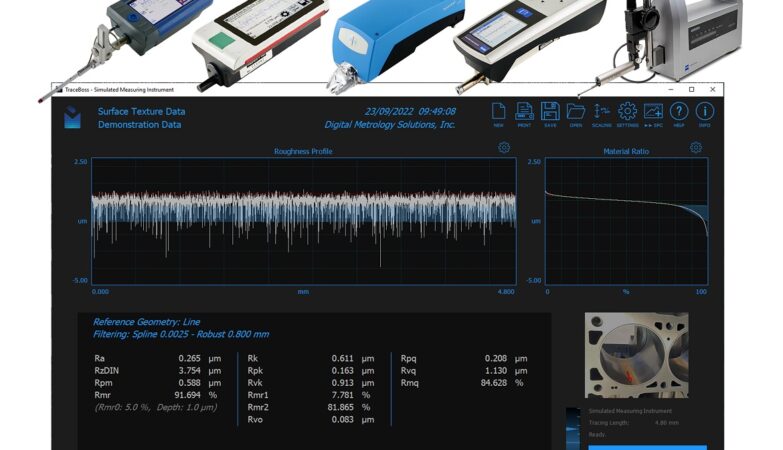

Hypoid gears are particularly challenging in terms of low noise levels because they are high-frequency and therefore tend to transmit vibrations and sound radiation, which in turn leads to unpleasant noise development in the vehicle interior. To find the origin of the gear noise, Honda uses the high-resolution measuring instrument InfiniteFocus from Bruker Alicona. The form and roughness measuring system is the ideal solution for the automotive group for several reasons: On the one hand, it also measures steep flanks in high resolution, and on the other hand, it allows the filtering of roughness and waviness based on dense, high-resolution and areal 3D data.

Filter roughness and waviness

One of the biggest challenges in measuring waviness on gear flanks is to filter the waviness and roughness of the surface. For Honda, conventional 2D imaging techniques did not lead to the requested results. The waviness is often superimposed by tool marks caused by e.g. milling cutters, which makes it challenging to isolate them completely from the roughness. 2D surface profiling methods or tactile measuring systems, which only capture single profile lines, are only partly suitable for this purpose. The optical, area-based 3D measuring system InfiniteFocus offers more possibilities here. Naoto Syukushima from the Powertrain Prototyping Department explains: “Ra values are not sufficient to verify the real surface state of flanks, as they only capture single profile lines. With area-based Sa-values, on the other hand, we can map surface features over the entire surface and then completely isolate them from the waviness using various filtering methods.” The results of this analysis have enabled Honda to adapt the manufacturing process of hypoid gears and, consequently, to help prevent negative noise development in the production of hypoid gears.

Measure steep flanks faster

High-resolution and repeatable measurements even with difficult to access geometries such as steep flanks is another benchmark that distinguishes InfiniteFocus from other metrology providers, according to Honda. This is what Naoto Syukushima says about the original need for a new measuring system: “The cooperation with Bruker Alicona started with the fact that we were looking for a measuring device that could also measure steep flanks.” He continues: “The system we used before no longer met our requirements. With InfiniteFocus we measure faster and get much more meaningful information. We have become much more efficient!” According to Honda, other aspects that have also contributed to this increase in efficiency are the high level of user-friendliness of the 3D measuring system, the 3D color information for quick and easy identification of wear, and the high measuring performance for flanks with different surface finishes. The latter is due to wear or different stages of wear and the associated different reflection properties of the flank. Syukushima mentions yet another benefit: “Our components often measure 250mm x 250mm. Other measuring systems that we have tested could not be used for this measuring volume.”

For Honda, there is one more decisive factor InfiniteFocus offers to successfully achieve the application of waviness analysis. “We can export the 3D and then apply our own analysis procedures. In our case, these are frequency analysis methods,” explains Syukushima. Honda has thus set a new standard in the quantification of waviness on gear flanks. The patent on their process proves the major impact and leadership in this sector.

Areal based 3D measurement of a gear flank. Surface features are mapped.

![]()

![]()

By using dense and areal 3D data, waviness is quantified. Also, as Honda has done, frequency analysis methods can be applied.