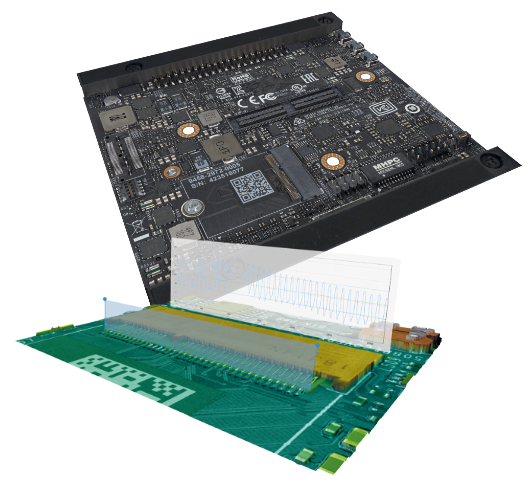

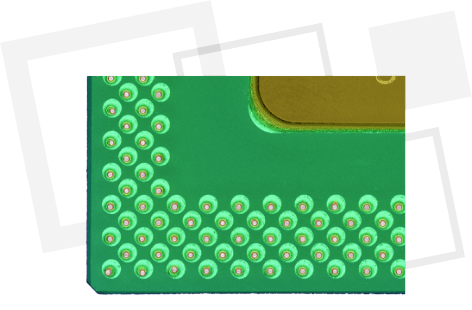

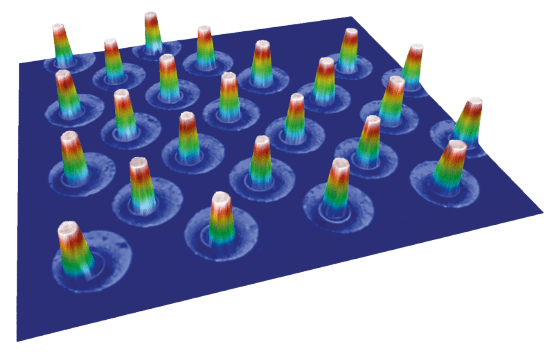

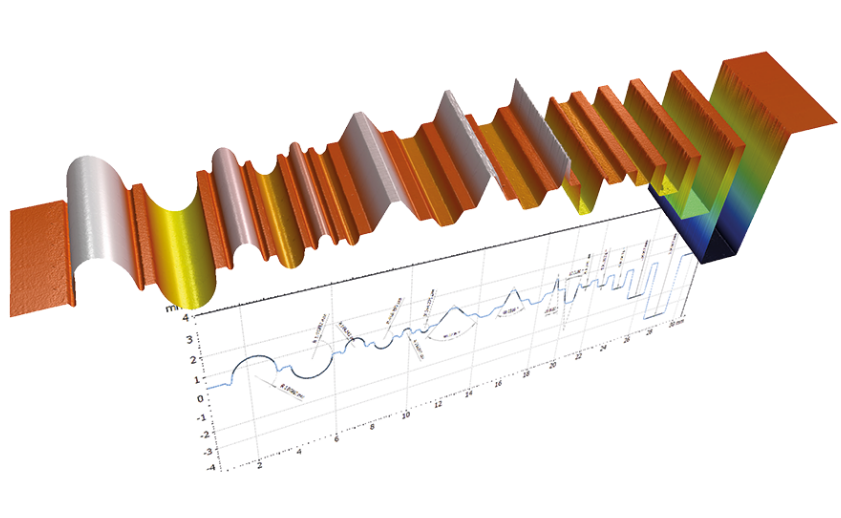

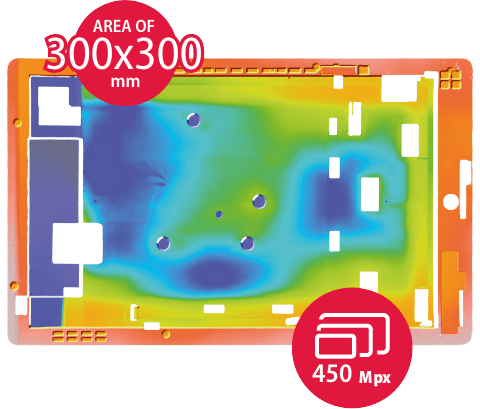

The S wide 3D profiler is a dedicated system designed to rapidly measure large sample areas up to 300 x 300 mm. It provides all the benefits of a digital microscope integrated into a high resolution measuring instrument. Extremely easy-to-use with one single button acquisition.

Features: S wide 3D Profiler

Solutions

Large Area 3D Optical Metrology System

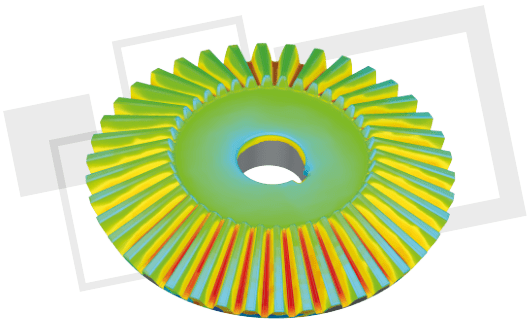

- Advanced manufacturing

- Archaeology & Paleontology

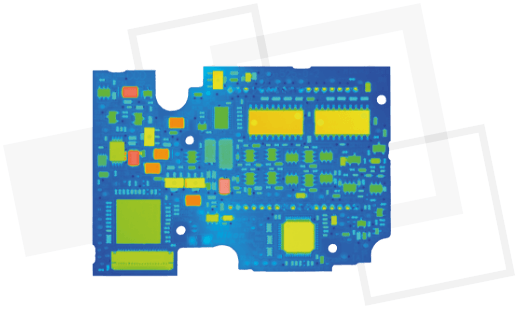

- Consumer electronics

- Medical devices

- Molding

- Optics

- Watch industry

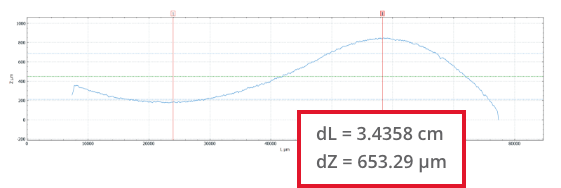

Sub-micron height repeatability over entire extended area

One-shot height measurement up to 40 mm without Z scanning

Bi-telecentric lenses with very low field distortion providing accurate metrology

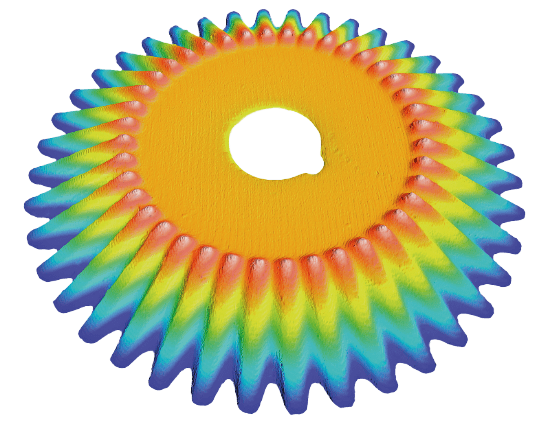

Form deviation from 3D CAD models providing the geometric difference and tolerance measurement

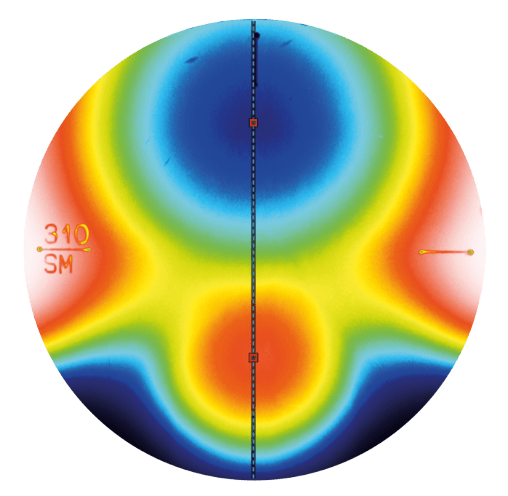

Traceability

Calibration of surface texture measuring instruments

All our systems are manufactured to deliver accurate and traceable measurements. Systems are calibrated using traceable standards following the ISO 25178 guidelines of part 7 for the Z amplification factor, XY lateral dimensions, flatness error, as well as parcentricity and parfocality.

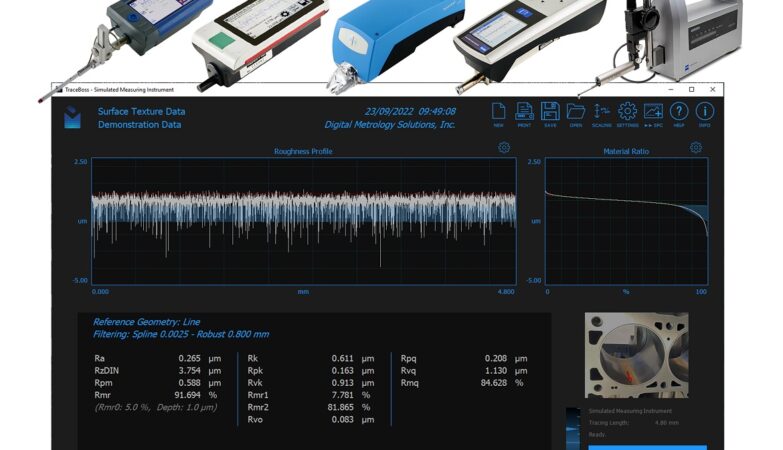

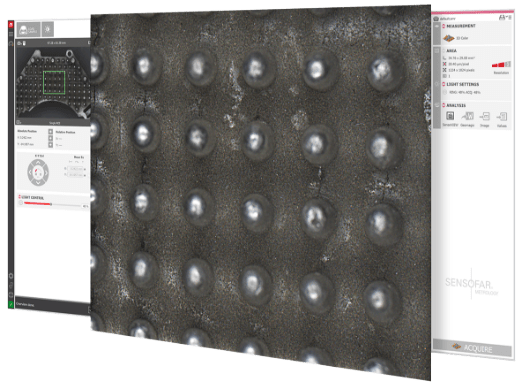

Software

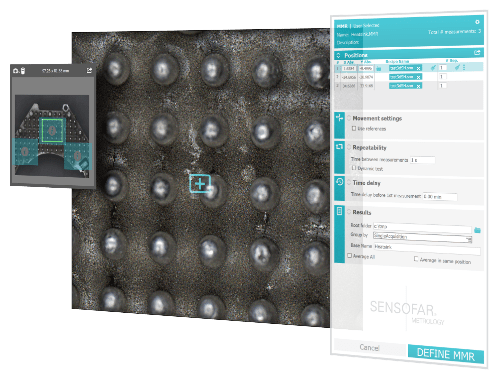

SensoSCAN S wide

Clear, intuitive and user-friendly interface

Software drives the system with its clear, intuitive, and user-friendly interface. The operator is guided through the 3D environment, delivering a unique user experience.

Optional modules

Extended measurements

SensoSCAN’s extended measurement module allows the user to easily define the measurement layout. Wide areas of up to 450 million pixels are possible.

Automating procedures

Automated measurements are obtained using the Recipes tool, which is a customizable facility for creating quality control procedures. It is extremely easy to define procedures for automating measurements with sample identification and automatic fiducials recognition.

Specifications

Technology

Fringe Projection

Light sources

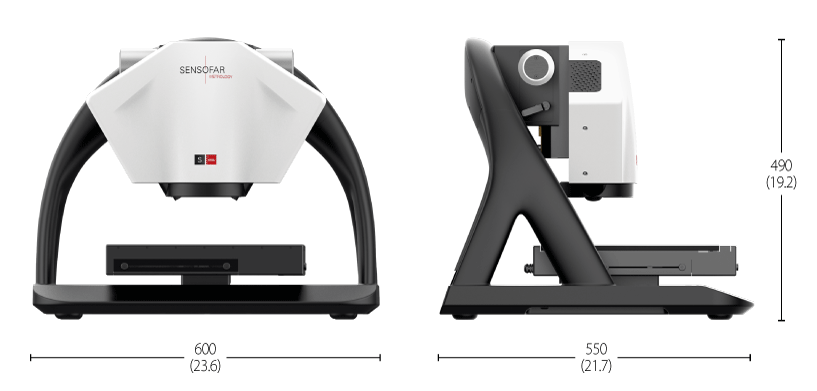

Dimensions

mm (inch)

Objective lenses

| MAG | 0.243X |

| NA | 0.015 |

| WD (mm) | 80 |

| FOV1 (mm) | 34.7 x 29.1 |

| Spatial sampling2 (µm) | 14.2 |

| Optical resolution3 (µm) | 9.35 |

XY performance

| XY | Manual | Motorized | |

| M | XL | ||

| Travel range (mm) | 150 x 100 | 154 x 154 | 302 x 302 |

Accuracy and repeatability

| Standard | U, σ |

| Step height | U=2.5 µm, σ= 0.05 µm |

| Area roughness (Sa) | U=1 µm, σ=0.01 µm |

| Profile roughness (Ra) | U=1 µm, σ= 0.05 µm |

Computer & Operating system

| Computer | 8th generation Intel® Core™ i7 Processor Display 3840×2160 pixels resolution (4K)(27″) |

| Operating System | Microsoft Windows 10, 64-bits |

To know more, please check Sensofar.